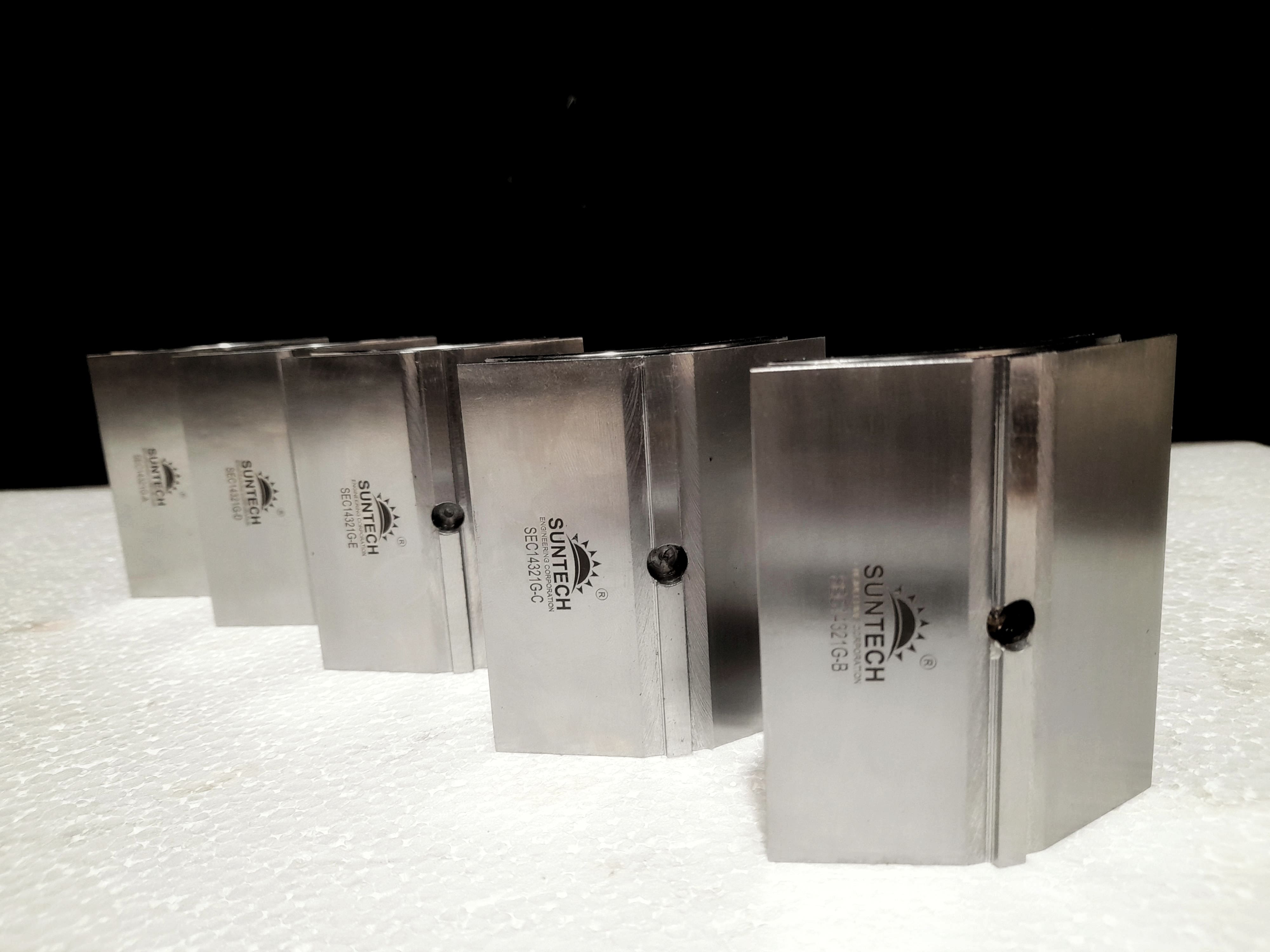

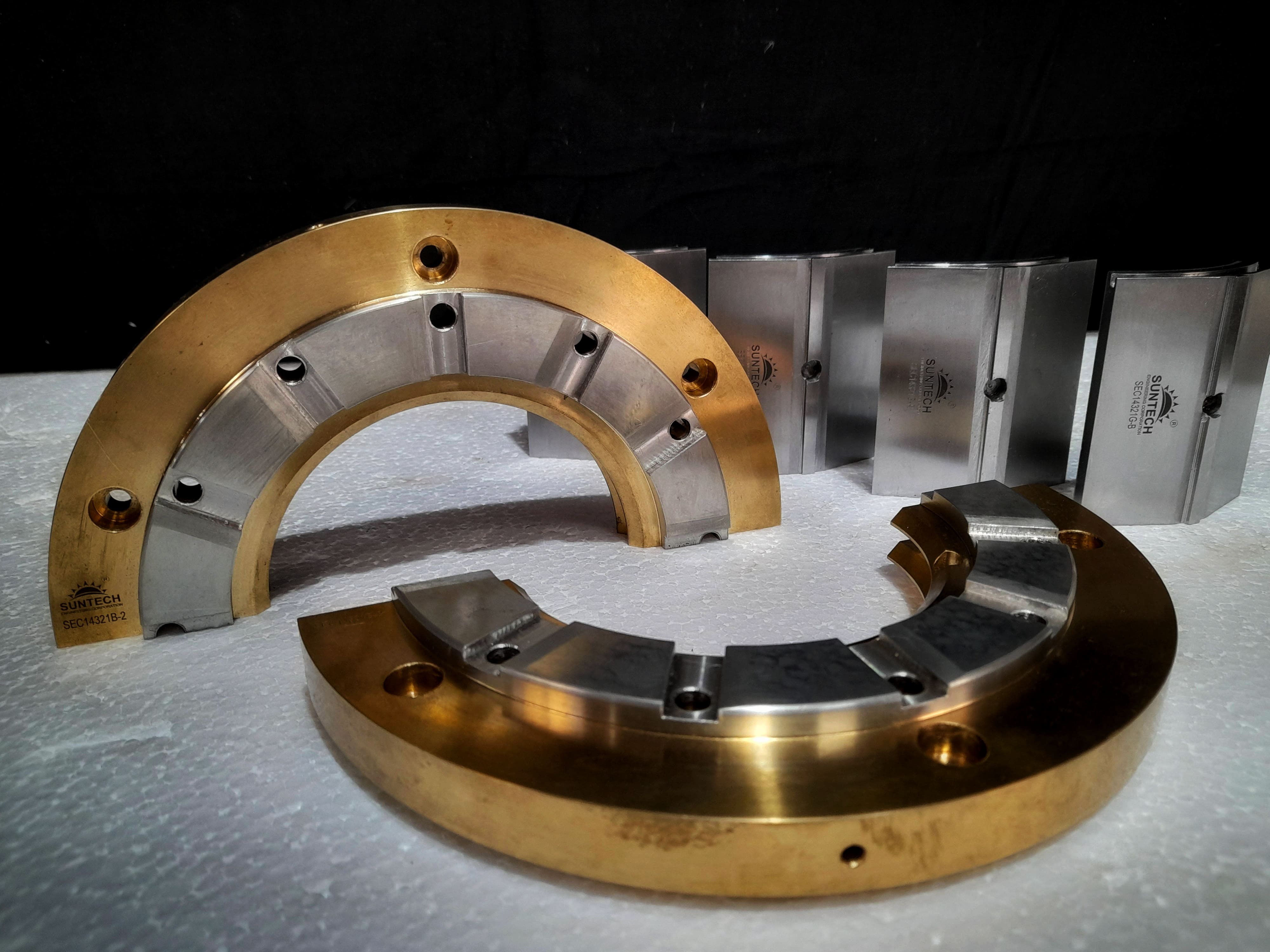

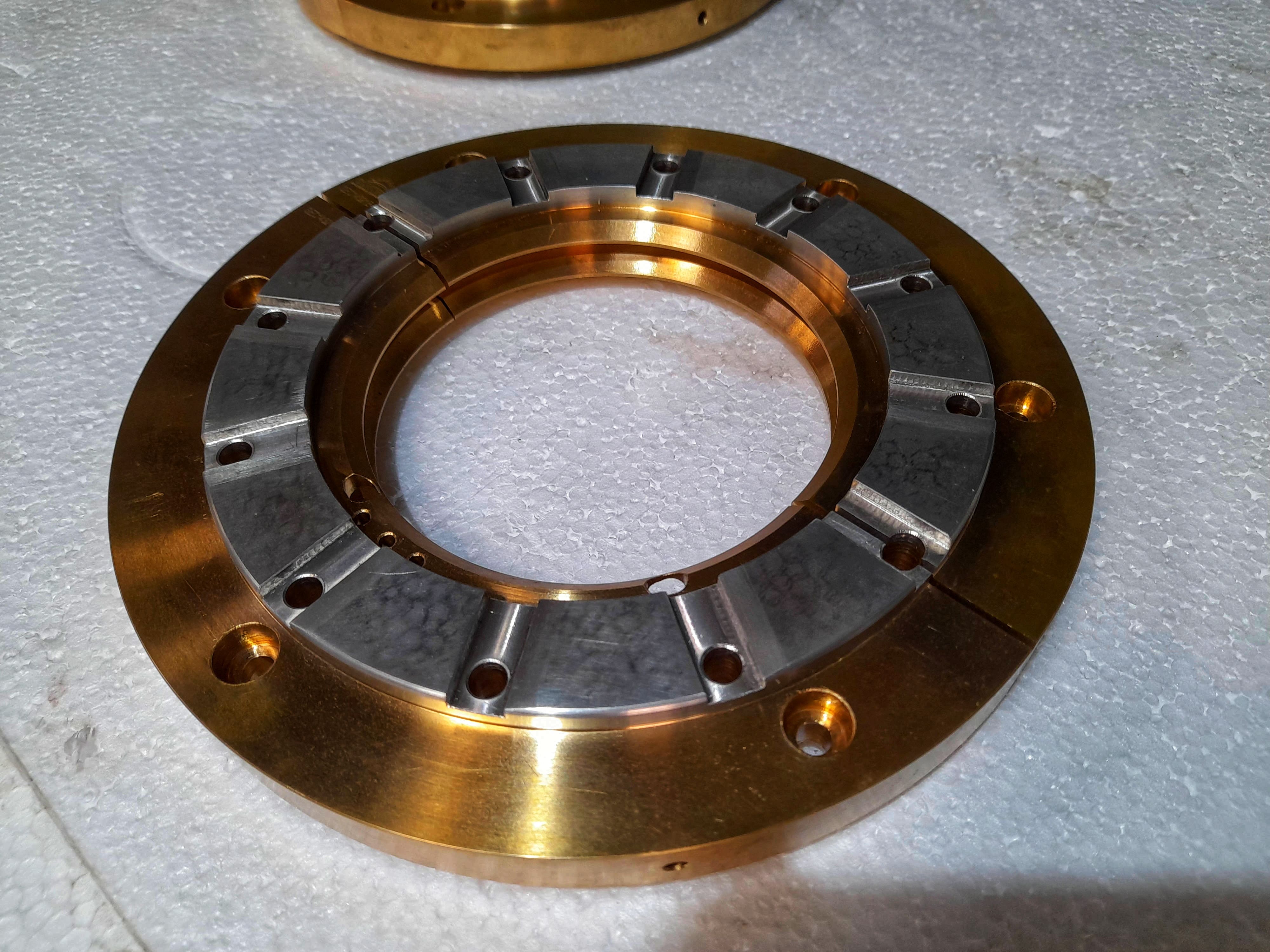

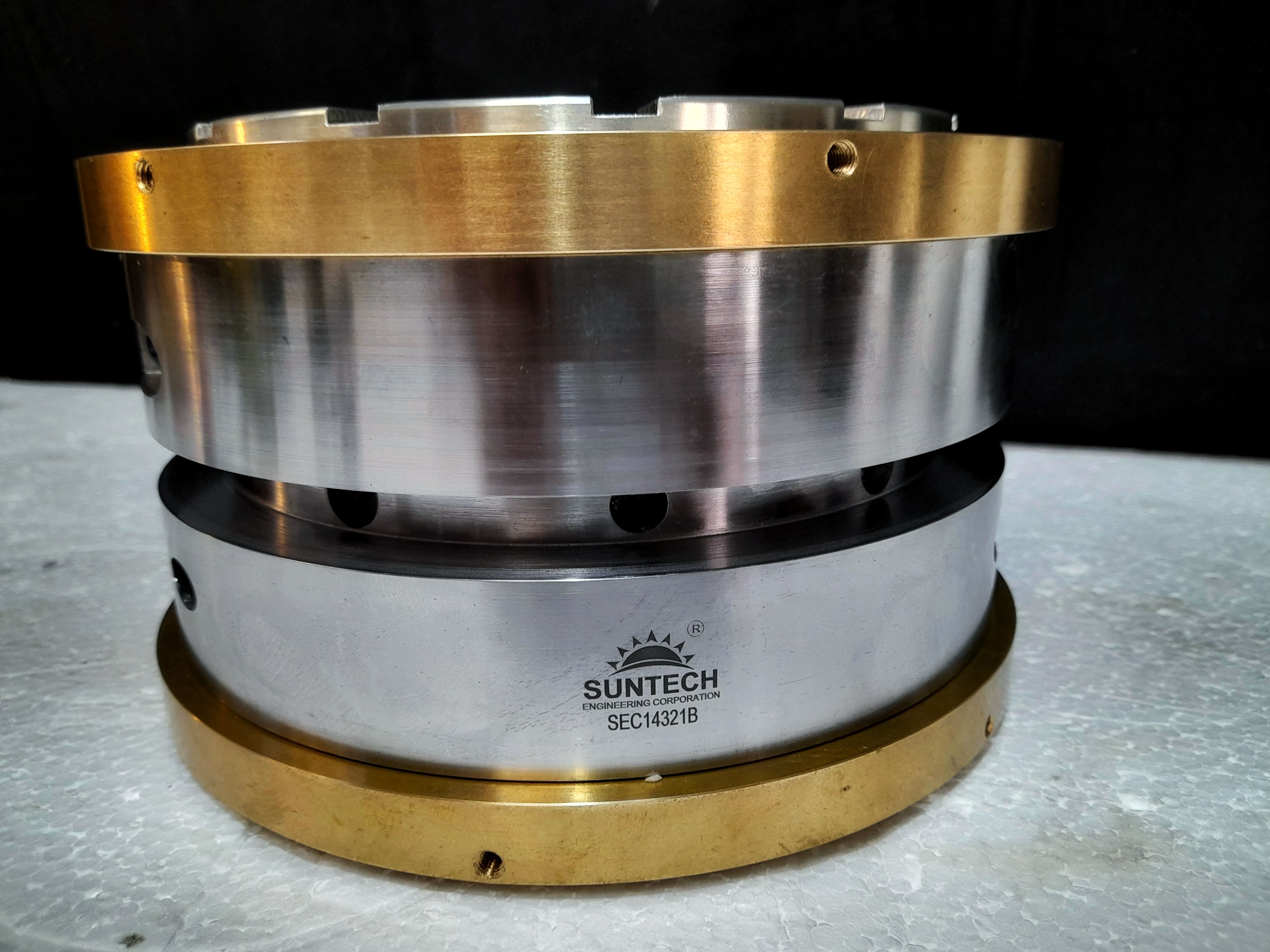

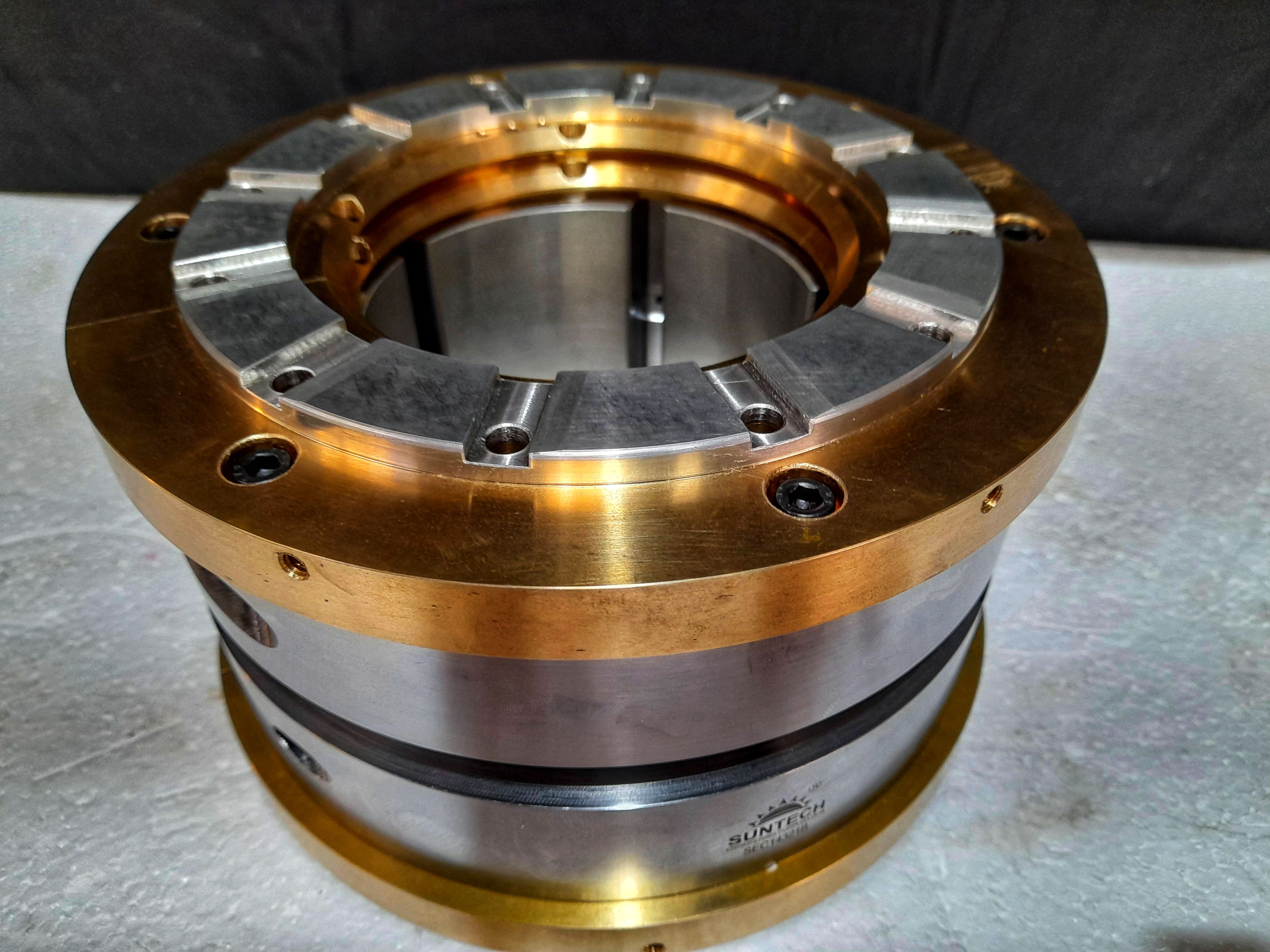

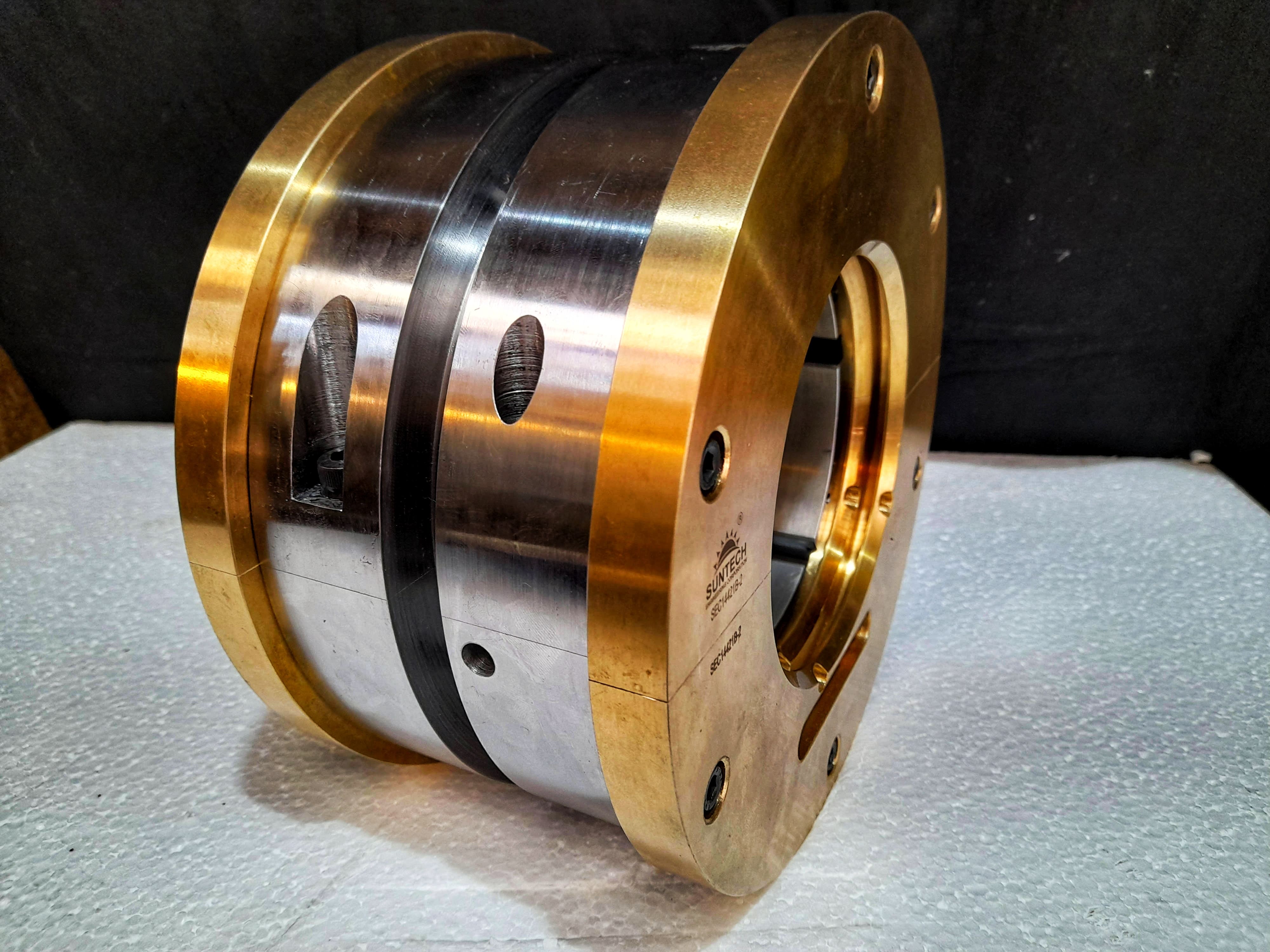

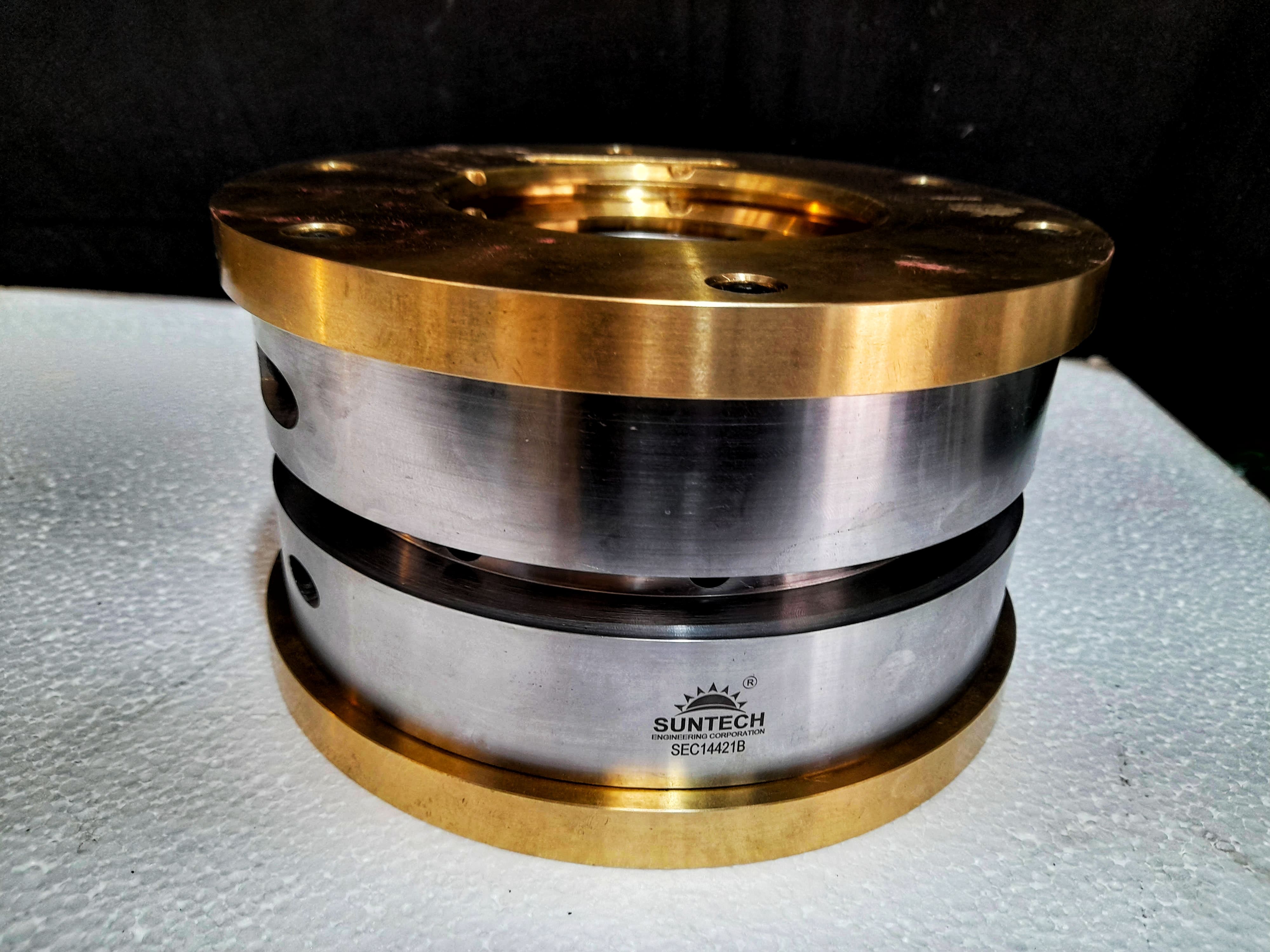

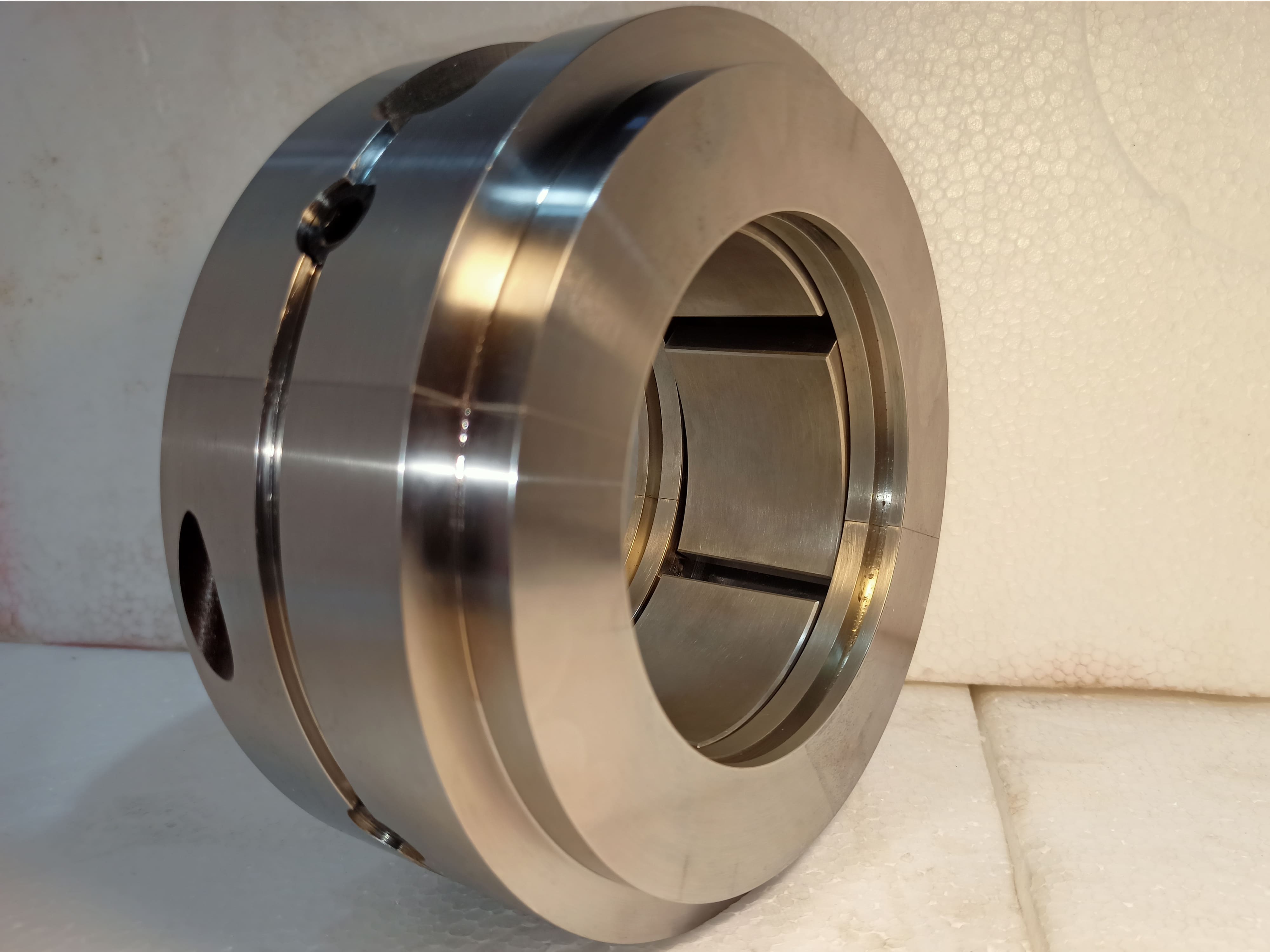

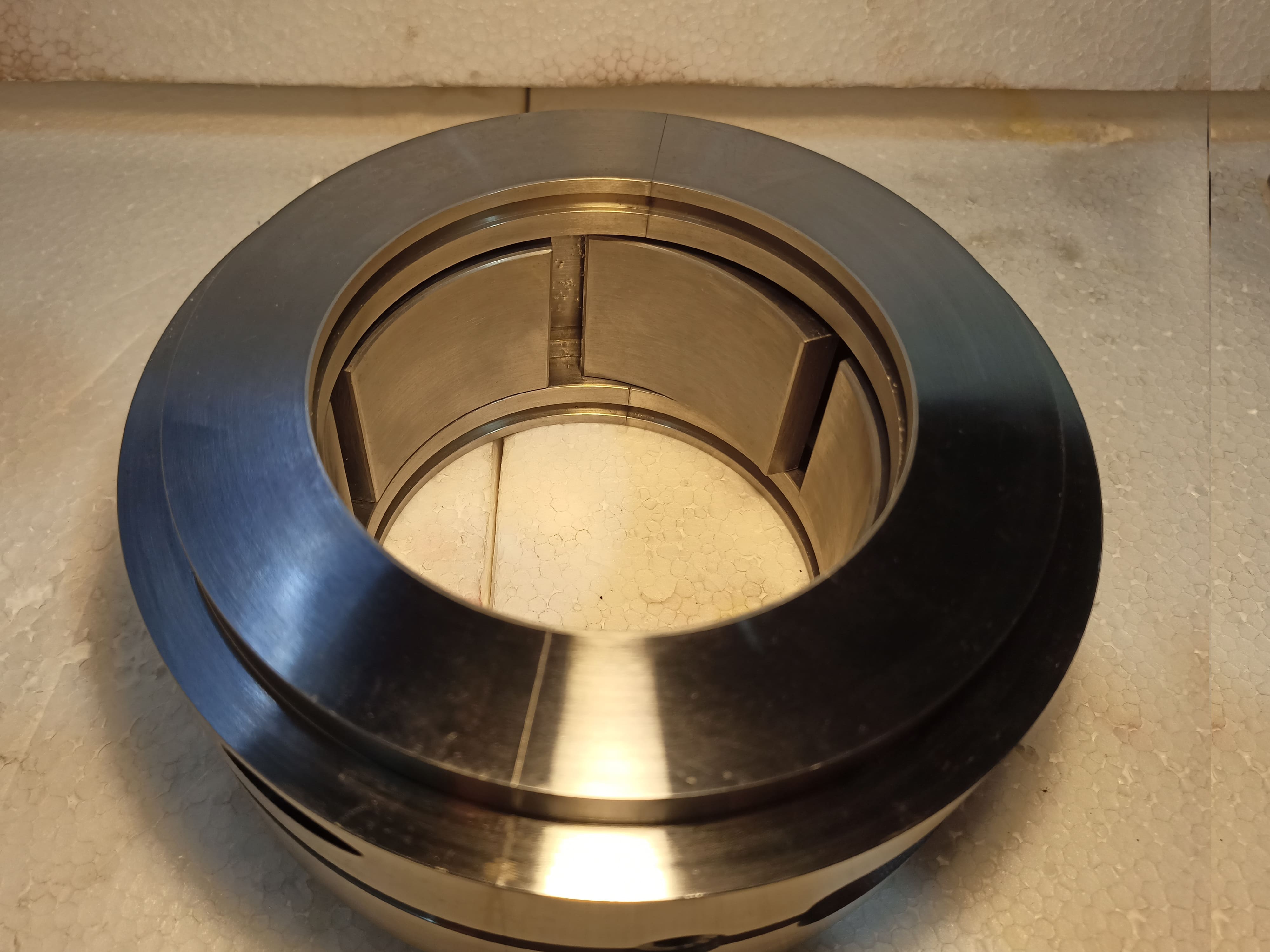

Tilting Pad Journal Bearing Assembly

Suntech® slide bearings are usually designed based on the principle of hydrodynamic

lubrication which increases its reliability. When the calculation design and

manufacturing conditions permit this type of lubrication, the slide bearings will

fulfil all the requirements expected of them.

It has been proven that plain cylindrical bearings built-up its carrying oil

wedge by making possible clearance between bearing shell and shaft due to its

eccentric position (converging film). Now a days various special geometry design has

been implanted which are also based on hydrodynamic calculation as per DIN 31657.