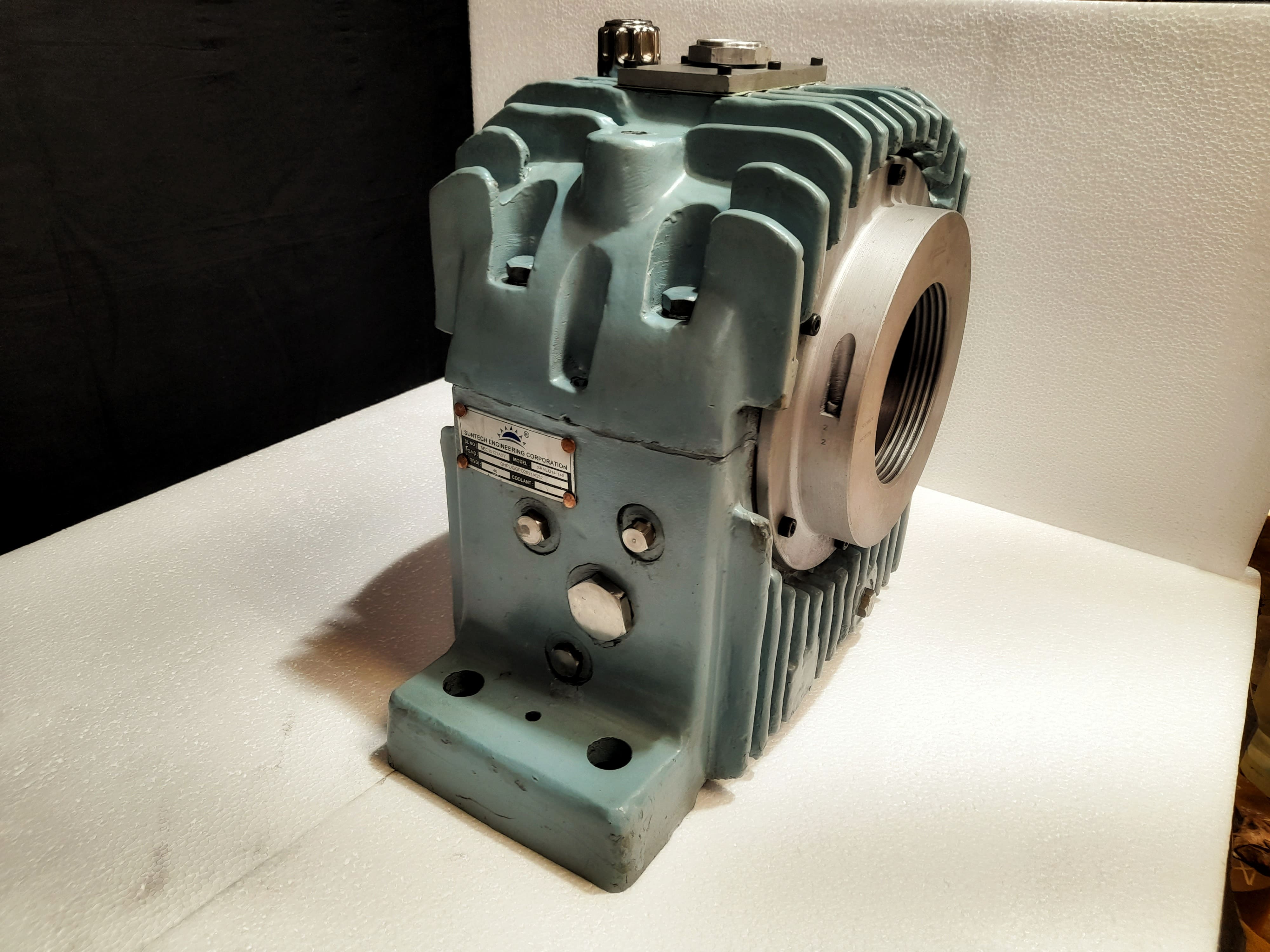

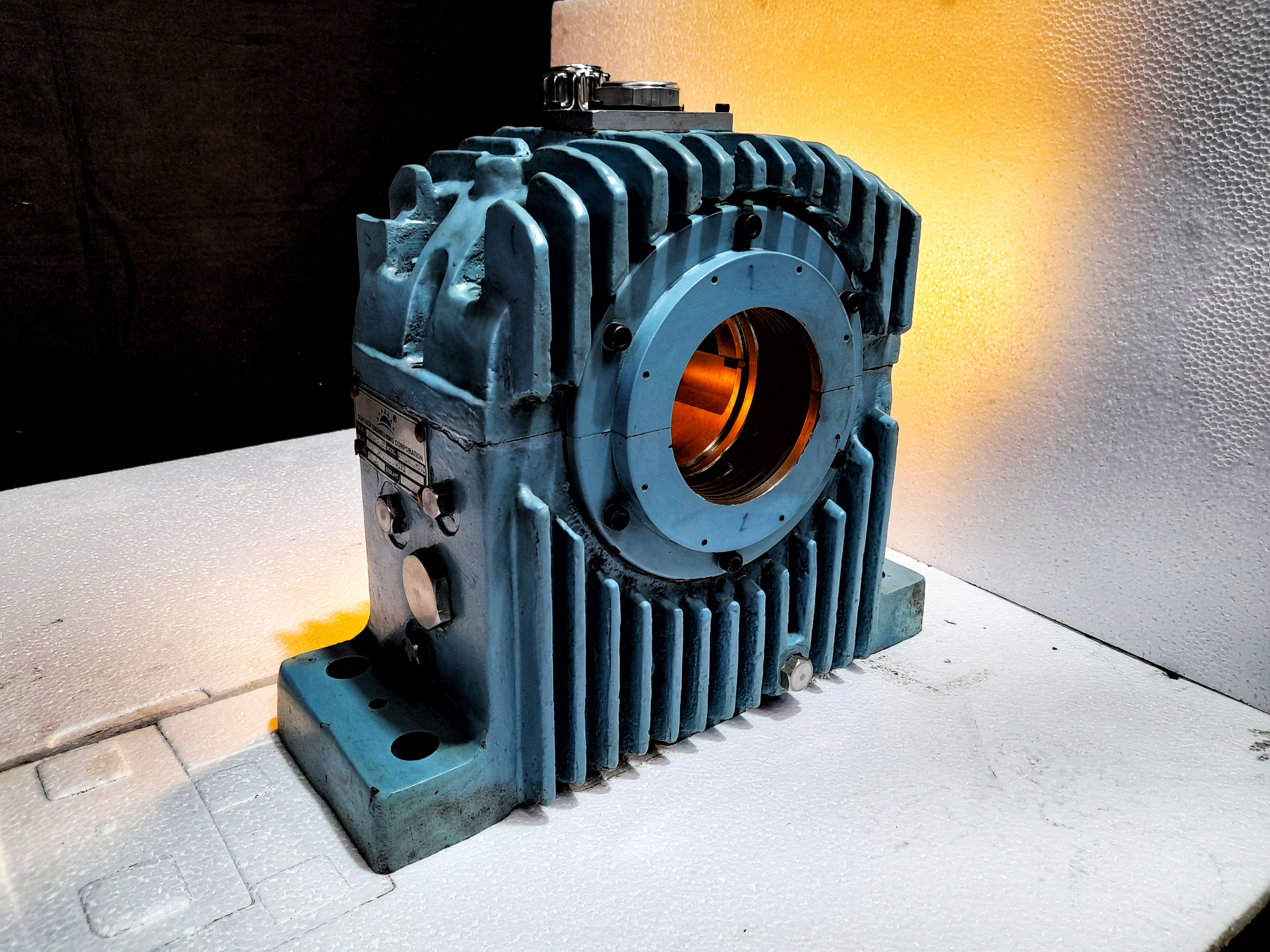

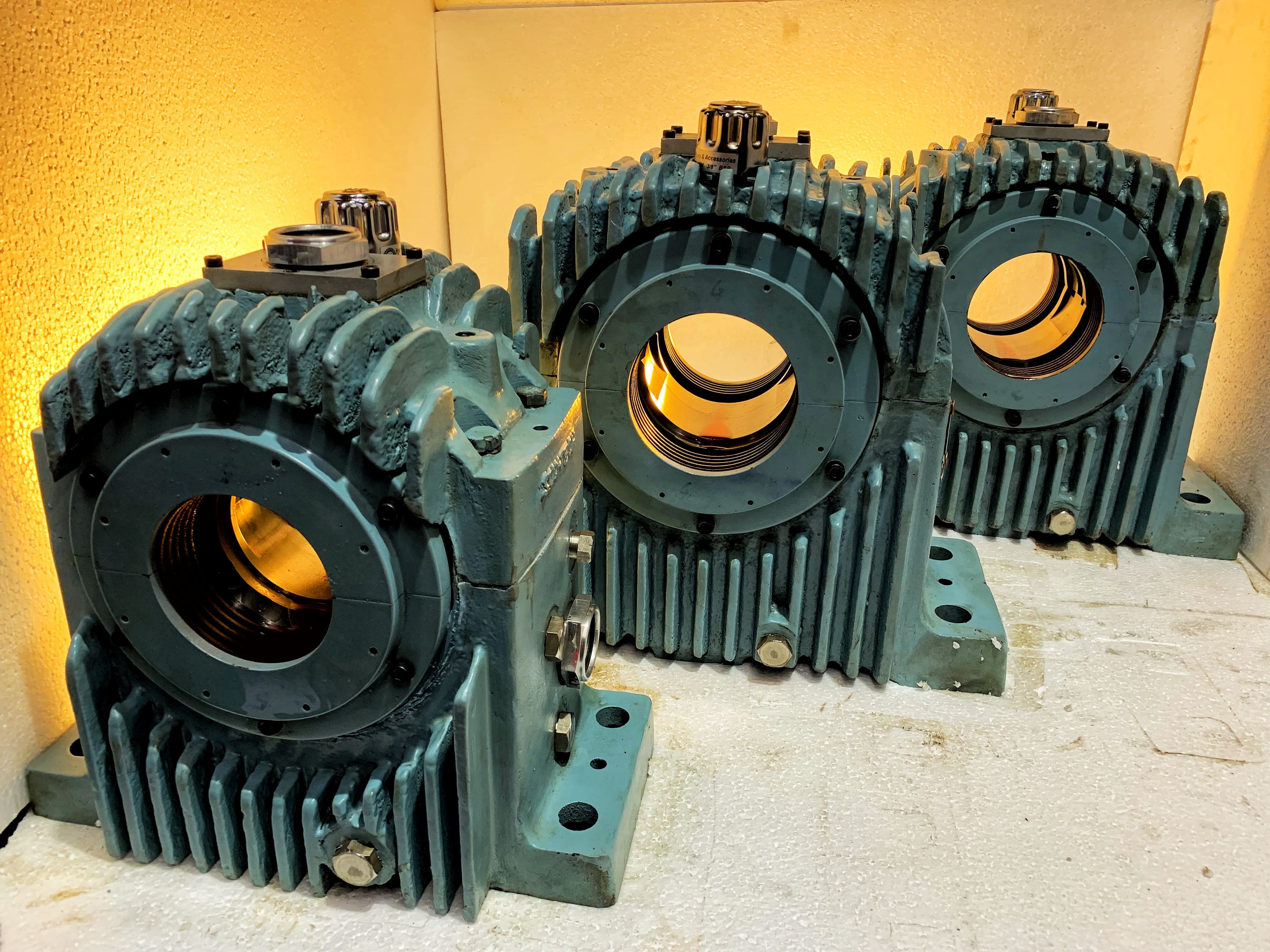

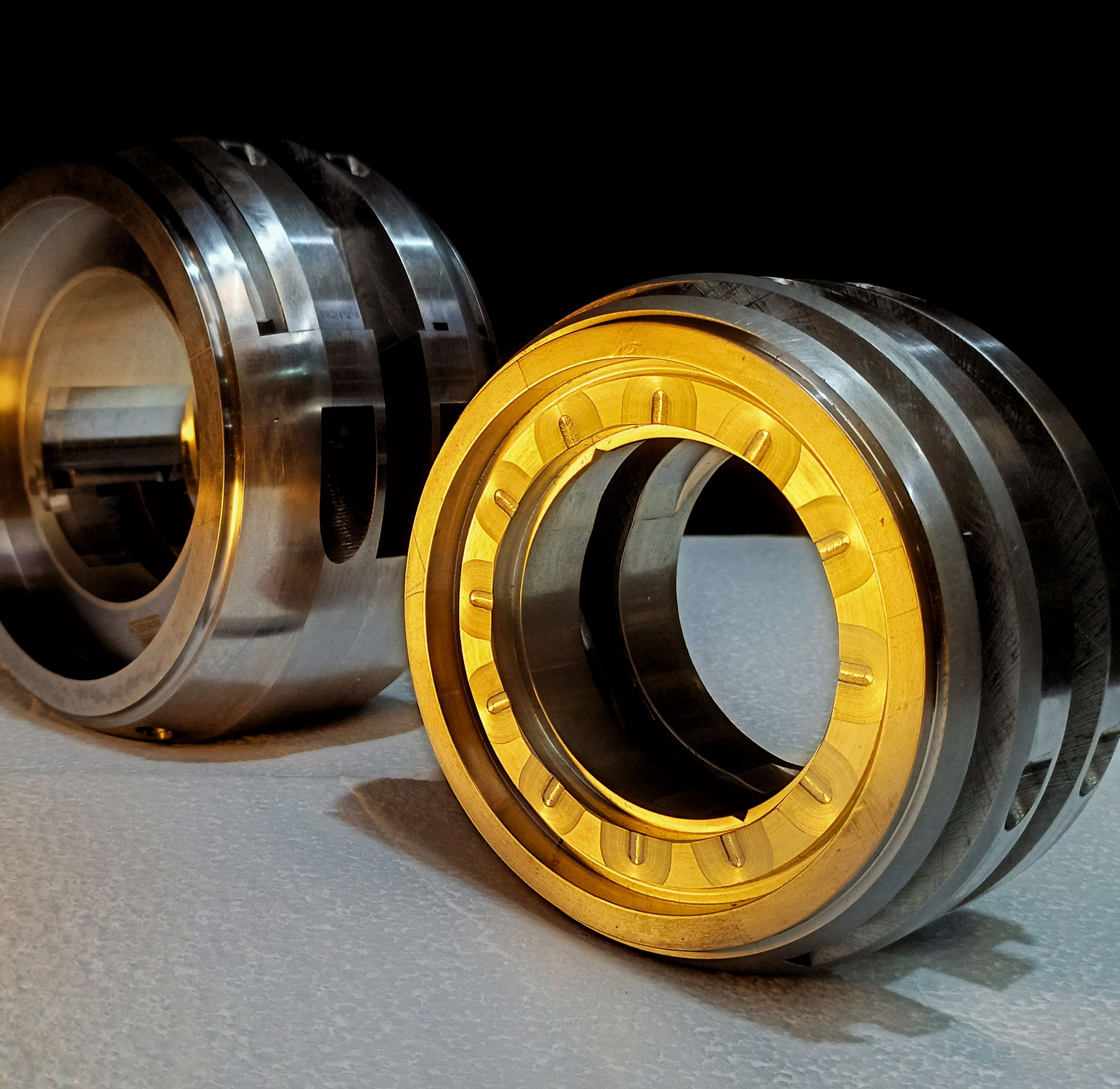

DIN Standard Bearing

Assembly

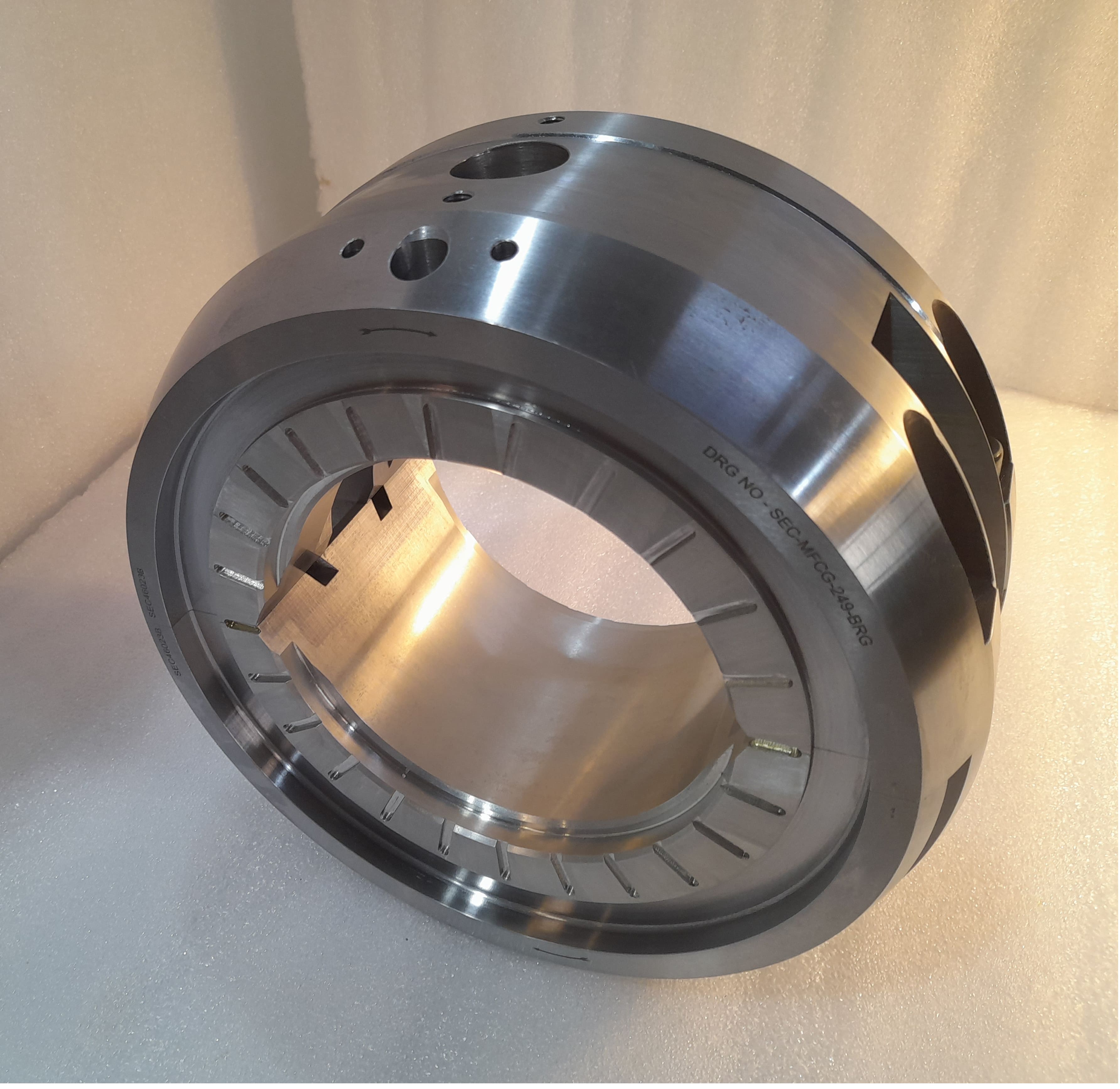

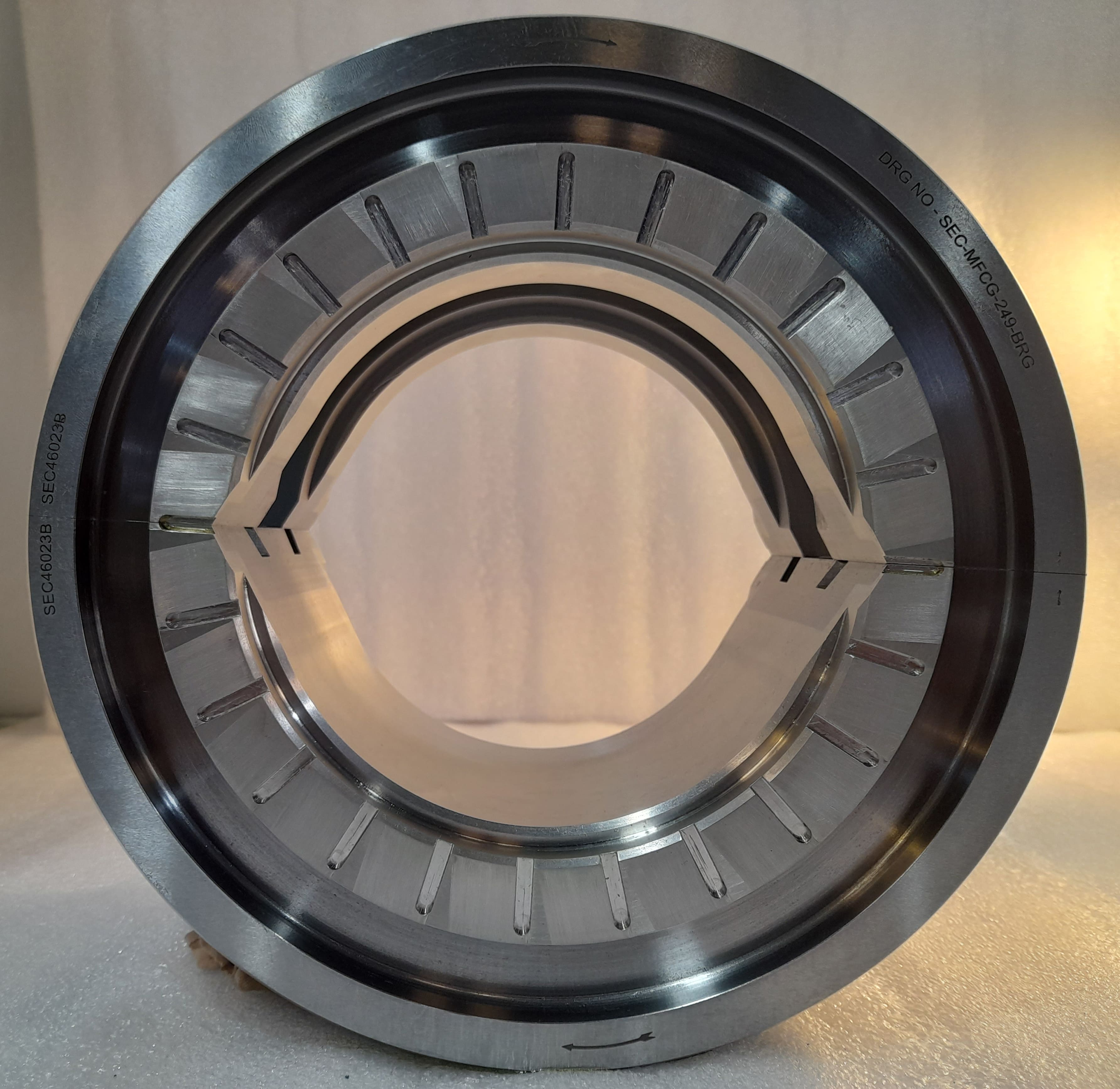

DIN Standard Bearing

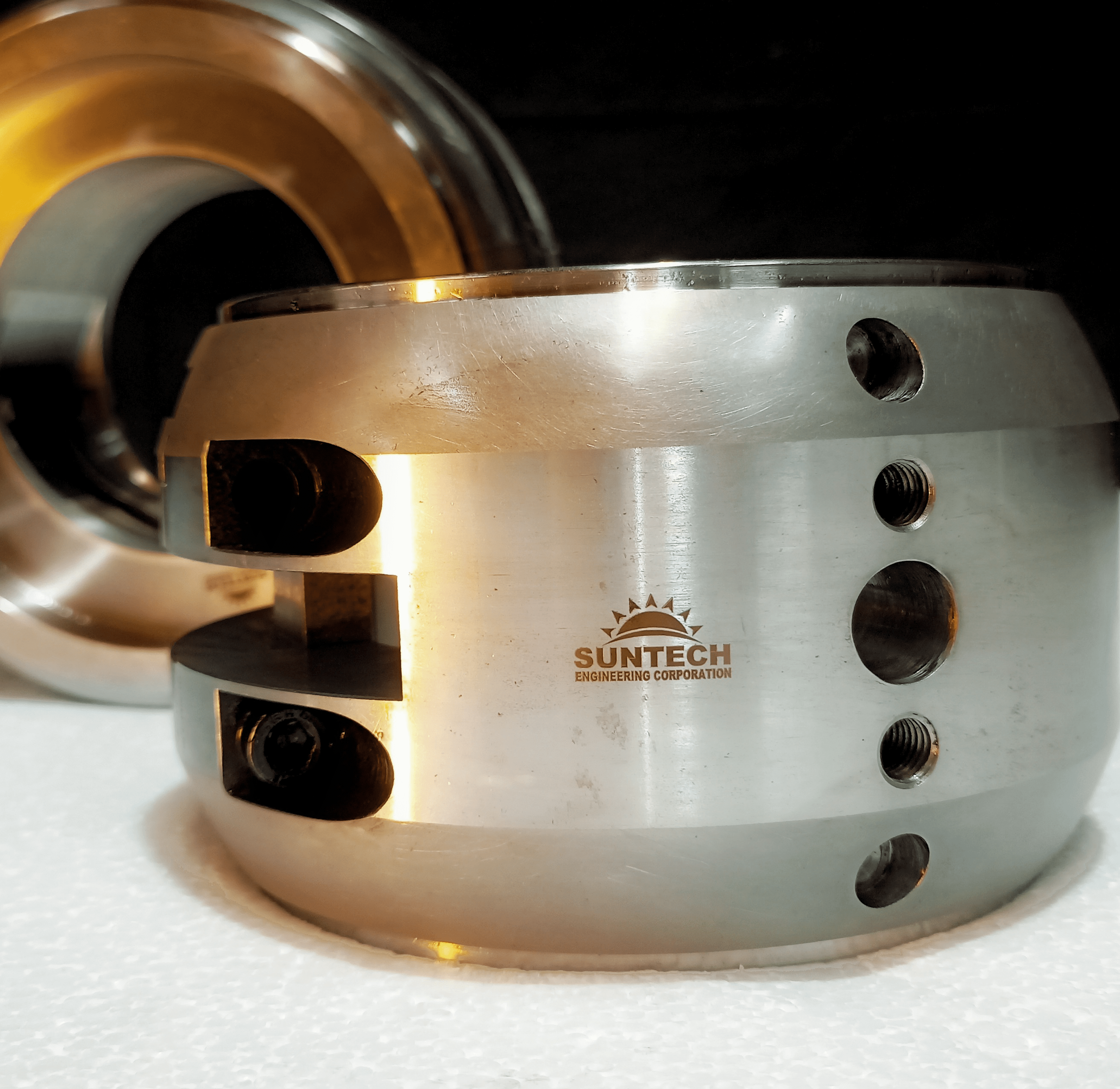

DIN standard Bearings DIN standard Bearings along with it's suitable Housings together and other required accessories makes a complete assembly. Basically there are three types of standard assemblies, which are available according to their applications.